Bridge maintenance equipment manufacturing - we specialize!

+Split design, tailor-made;

+Small space, easy to navigate;

+Installation and disassembly require no external force; +Intelligent control, powerful functions;

Specially designed and crafted for every project; Split cage design, stainless steel interior; Small space, easy to assemble and disassemble.

Enclosed space enhances a sense of security; Large space inside the cage, fast running speed, smooth starting and braking; Structural anti-corrosion, far exceeding the lifespan of the main structure of the bridge.

Each component undergoes effective shot blasting treatment after welding to remove rust and oxide layers, harden the metal surface, and eliminate welding stress; All hot-dip galvanizing treatment achieves the best protective effect.

Based on the application experience of domestic construction elevators, the industry's unique standard section connection bolt anti reverse safety design can effectively avoid major equipment accidents; And set up a manual lowering function.

The operation is more convenient and simple, using frequency conversion control and equipped with automatic leveling and other functions. And there are auxiliary functions such as floor call device, automatic lubrication device, facial and fingerprint recognition system, video surveillance system for users to choose from.

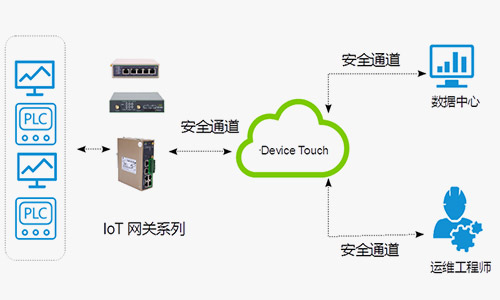

Support remote monitoring system, effectively connect with the site, and implement real-time monitoring of its operating conditions; Proactively providing customers with remote fault analysis and solutions to prevent various hidden dangers during elevator operation; Enhance auxiliary functions such as equipment management, energy conservation, and consumption reduction; Support operating system upgrades.

| Type number | SC100 | S100 |

|---|---|---|

| Rated load capacity (Kg) | one thousand | one thousand |

| Motor power (Kw) | 2×11 | 2×15 |

| Working speed (m/min) | 0-45 | 0-45 |

| Maximum lifting height (m) | three hundred | three hundred |

| Cage size (m) | 1.8×1.75×2.2 | 1.8×1.75×2.2 |

| Standard section size (mm) | 650×300×1508 | 650×300×1508 |

| Distance between the center of the guide rail bracket and the wall (mm) | 310~1000 | 310~1000 |

| Installation interval of attachment frame (m/track) | four point five | four point five |

| Tilt angle (°) | fifteen | fifteen |

| Minimum curvature radius (m) | two hundred | two hundred |