Safe, efficient, and more professional

+Comprehensive functionality

+Energy saving and environmentally friendly

+Small starting current +variable length of flat bridge

The smoke tower multifunctional lift is a professional construction equipment used for various cooling tower constructions. It has multiple functions and can simultaneously transport steel bars, concrete, and construction personnel, greatly improving construction efficiency; Avoiding duplicate equipment purchases and saving funds; Improving construction technology has played a driving role in the development of the construction industry for electric power tower projects.

The construction platform is suspended on the standard section guide rail, which can be locked by itself or lifted up and down by the power of the cage. The platform can be extended or shortened according to the progress of the project; The concrete hopper has a large capacity, making it easy to receive and release materials; The steel bars are easy to lift and bind, and can be accurately placed on the construction platform.

The main components undergo shot blasting treatment after welding to remove rust and oxide layers, harden the metal surface, eliminate welding stress, improve paint adhesion, and use more environmentally friendly advanced processes for painting. The normal protective effect can reach more than 10 years.

Based on the application experience of domestic construction elevators, the industry's unique standard section connection bolt anti reverse safety design can effectively avoid major equipment accidents

The operating system adopts frequency conversion control, which enhances the adaptability of the elevator on site, reduces the starting current, and has no impact on surrounding equipment; There are floor call devices, automatic leveling functions, automatic lubrication devices, facial and fingerprint recognition systems, electric flap doors, and more auxiliary functions available for users to choose from.

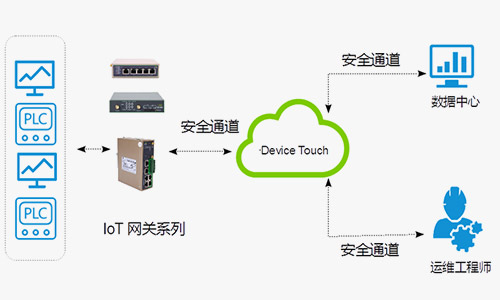

Support remote monitoring system, effectively connect with the site, and implement real-time monitoring of its operating conditions; Proactively providing customers with remote fault analysis and solutions to prevent various hidden dangers during elevator operation; Enhance auxiliary functions such as equipment management, energy conservation, and consumption reduction; Support operating system upgrades.

| Type number | SC200/200 | SC200/200 |

|---|---|---|

| Rated load capacity (Kg) | 2000/2000 | 2000/2000 |

| Motor power (Kw) | 3×15/3×15 | 3×15/3×15 |

| Working speed (m/min) | 0-56 | 0-56 |

| Maximum lifting height (m) | three hundred | four hundred |

| Cage size (m) | 2100×1100×2200 | 2100×1100×2200 |

| Standard section size (mm) | 650×650×1508 | 800×800×1508 |

| Installation interval of attachment frame (m/track) | 6~9 | 6~9 |

| Flat bridge length x width (m) | 9.0×2.0 | 9.0×2.0 |

| Hopper capacity (M ³) | zero point seven | zero point seven |

| Suspended steel bar length/weight | 9.0m/600kg | 9.0m/600kg |