Safe, efficient, and more professional

+Flexible angle adjustment

+Fast transition time

+Adopting frequency conversion technology +maintaining power grid safety

The scope of application is broader and more professional, mainly in bridge engineering, and can also be used for a long time in ordinary engineering; By adopting new technologies, humanized design, and advanced manufacturing processes, the applicability, reliability, and comfort of the product have been improved, with a maximum lifting height of over 300 meters and a maximum tilt angle of 15 °; The product has reached the advanced level domestically.

Changing the tilt angle as desired, only a small component needs to be replaced to meet the engineering requirements of different angles; Reusable, convenient and fast transition, and can also be used as a regular construction elevator; Save objective costs for investors.

The main components undergo shot blasting treatment after welding to remove rust and oxide layers, harden the metal surface, eliminate welding stress, improve paint adhesion, and use more environmentally friendly advanced processes for painting. Under normal circumstances, the protective effect can reach more than 10 years.

Based on the application experience of domestic construction elevators, the industry's unique standard section connection bolt anti reverse safety design can effectively avoid major equipment accidents.

The operating system adopts frequency conversion control, which enhances the adaptability of the elevator on site, reduces the starting current, and has no impact on surrounding equipment; There are floor call devices, automatic leveling functions, automatic lubrication devices, facial and fingerprint recognition systems, electric flap doors, and more auxiliary functions available for users to choose from.

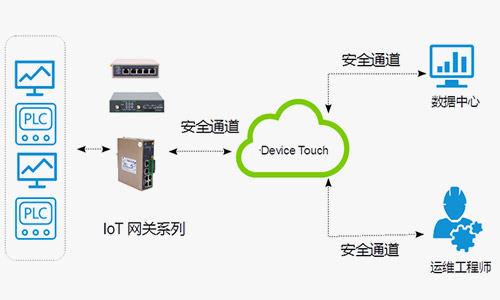

Support remote monitoring system, effectively connect with the site, and implement real-time monitoring of its operating conditions; Proactively providing customers with remote fault analysis and solutions to prevent various hidden dangers during elevator operation; Enhance auxiliary functions such as equipment management, energy conservation, and consumption reduction; Support operating system upgrades.

| Model | SC200 | SC200/200 |

|---|---|---|

| Rated load capacity (Kg) | 2000 | |

| Motor power (Kw) | 2 × 15 | td>2 × 15/2 × 15|

| Working speed (m/min) | 0-45 | 0-45 |

| Maximum lifting height (m) | 300 | |

| Cage size (m) | 3.2 × 1.5 × 2.2 | 3.2 × 1.5 × 2.2 |

| Standard section size (mm) | 650 × 650 × 1508 | 650 × 650 × 1508 |

| Distance between the center of the guide rail frame and the wall (mm) | 3100-3400 | 3100-3400 |

| Installation interval of attachment frame (m/track) | 6 | 6 |

| Tilt angle (°) | 15 | |