1. Flat head design, beautiful appearance;

2. It can flexibly implement multiple types of variable arms to meet different user needs;

3. Wide scope of work, diverse work styles, and strong adaptability;

4. The lifting, slewing, amplitude changing, and jacking mechanisms are highly compatible with the TC5510 tower crane.

Multiple combinations of boom lengths can meet different needs of users. The structure of the crane arm has a variable cross-section, which reduces the self weight of the structure and has a long service life.

The lifting arm pull plate and balance arm pull rod are designed with installation brackets, making installation and disassembly safer and more convenient.

The lifting crossbeam is designed with safety pins to ensure a safe and reliable lifting process.

The design between the rotating tower body and the upper support is a pin shaft connection, which provides more reliable performance.

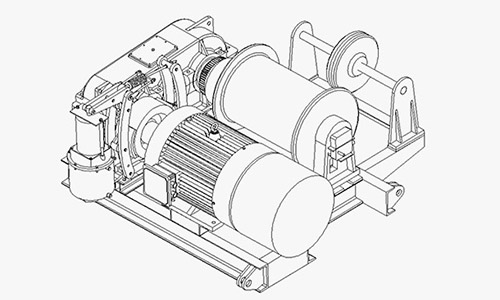

The lifting reducer is a four axis transmission, and the lifting mechanism drum is designed with a thick and short type to extend the service life of the steel wire rope.

| Name | Unit | Parameters | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Rated lifting moment | kN. m | 630 | r>|||||||

| Maximum lifting torque | kN. m | 870 | Maximum lifting weight | t | 6 | Operating range | m2-55|||

| Maximum working amplitude lifting weight | t | 1 | |||||||

| Lifting height | m | Magnification | >Independent | Attached | 2 | 40 | 140 | 4 | 40 | 70 |

| 2 | 4 | ||||||||

| Lifting Speed | m/min | 80 | 40 | 20 | |||||

| Lifting Weight | t | 1.5 | 3 | 3 | 6 | ||||

| Rotation speed | r/min | 0.62 | |||||||

| Variable amplitude speed | m/min | 40.5/2 | |||||||

| Lifting speed | m/min | 0.42 | |||||||

| Tower section size | m | 1.7 × 1.7 × 2.48 | |||||||

| Balance weight | t | n="6 ">13.9||||||||

| Operating temperature | ℃ | -20~+40 | |||||||

| Overall power | kW | 34.7 (excluding lifting motor) | |||||||