Building a website is simple

Efficient processing

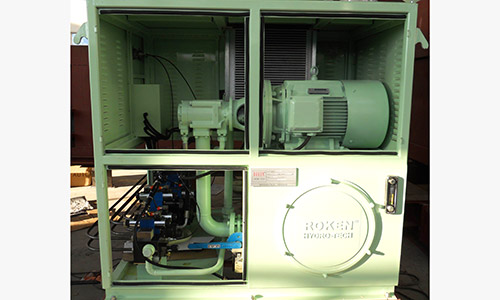

Efficient processing, sealed and environmentally friendly

Adapt to the unloading needs of various garbage collection methods

Adopting sealed compression treatment technology to avoid leakage.

Adopting a non rail design, garbage will not be carried into the back of the compression chamber.

Adopting advanced dual pump technology of both large and small sizes

Can automatically connect and separate the garbage bin and compressor

Equipped with a shock-absorbing device to effectively prevent equipment damage caused by excessive impact force during docking

Electric push rod can achieve automatic opening and closing of the traction hook

Full load warning function; Strong compression function; Emergency stop function; Strong withdrawal function.

| project | Company | parameter |

|---|---|---|

| Theoretical productivity of compressor | t/h | twenty |

| Garbage bin capacity | m³ | twenty |

| Whole machine model |

|

LYJSZG20 |

| Feeding volume | m³ | six |

| Push the first round of work back and forth time | s | thirty-five |

| Maximum compressive force | KN | three hundred and forty |

| Compressor dimensions L × W × H | mm | 4650×2380×1450 |

| Compression head dimensions L × W × H | mm | 2480×2000×800 |

| Net land occupation of garbage treatment workshop L × W | m | 13.3×15 |

| The total area of the garbage treatment workshop is L × W | m | 15.3 × 17 (excluding loading platform and ramp) |

| Power Supply | V/Hz | 380/50 |