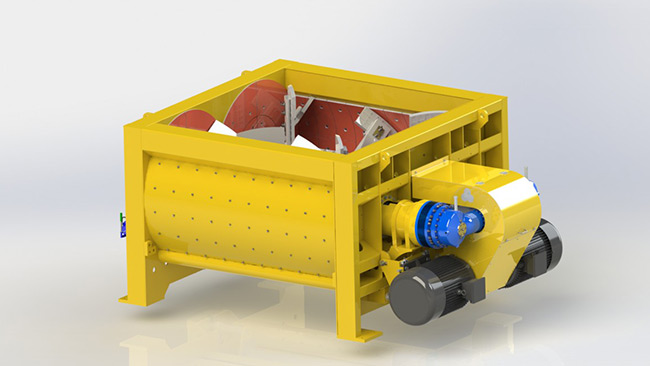

This series of products is mainly used as a supporting host for concrete mixing plants, suitable for various large and medium-sized prefabricated component factories, as well as industrial and civil construction projects such as high-speed railways, highways, bridges, water conservancy, and docks. It is a high-efficiency new machine that can mix lightweight aggregate concrete and various mortars.

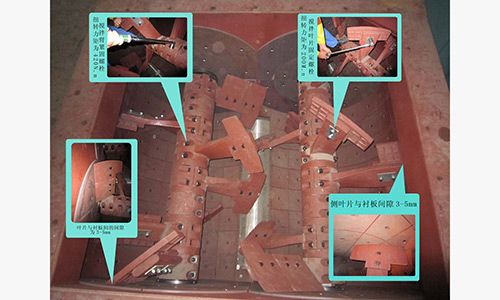

Standardized assembly process, strictly control the gap between the mixing blade and the arc liner plate to be uniformly within 5mm.

The overall post weld aging treatment of the mixing drum strictly ensures the center distance between the two main mixing shafts and the coaxiality between the large arc plate and the mixing shaft!

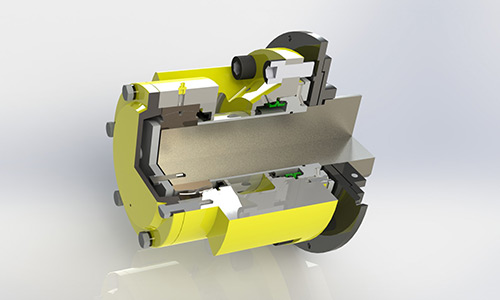

Adopting a new type of shaft end seal and using specialized equipment for seamless installation can ensure the reliable use of the shaft end seal and prevent leakage of grout.

The mixing arms, blades, and lining plates made with special techniques are sturdy and durable, making material mixing more ideal!

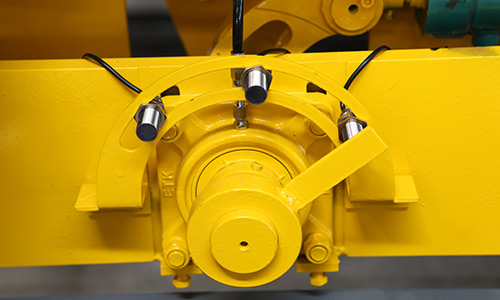

The unloading mechanism is equipped with three proximity switches to control the opening and closing status of the unloading door!

Adopting advanced centralized grease lubrication system, with four independent working lubrication points!

| Project | Unit | Parameters | Feed capacity | L | 2400 | Discharge capacity< | L | 1500 |

|---|---|---|---|---|---|

| Theoretical productivity | m ³/h | ≤ 90 | |||

| Maximum particle size of aggregate (pebble/gravel) | mm | 80/60 | |||

| Mixing arm | |||||

| Mixing blade speed | r/min | 26 | |||

| Mixing motor | Y2-200L-6 | ||||

| Power | kW | 2 × 30 | |||

| Electric concentrated oil pump power | kW | 0.05 | |||

| Hydraulic station motor power | kW | 2.2 | |||